One-stop Silicone Products Customization Service

NEWTOP Rubber is an experienced silicone rubber manufacturer.

At NEWTOP Rubber, you can get a reasonable price and comprehensive service for customized silicone solutions. Our OEM services cover the entire life cycle of custom silicone products. All processes including design, mold making, prototype testing, molding, printing, packaging, etc. can be customized according to your specific business needs.

With extensive manufacturing capabilities and optimized in-house processes, we can accept complex custom orders and turn your concepts into products most efficiently, helping you grow your business.

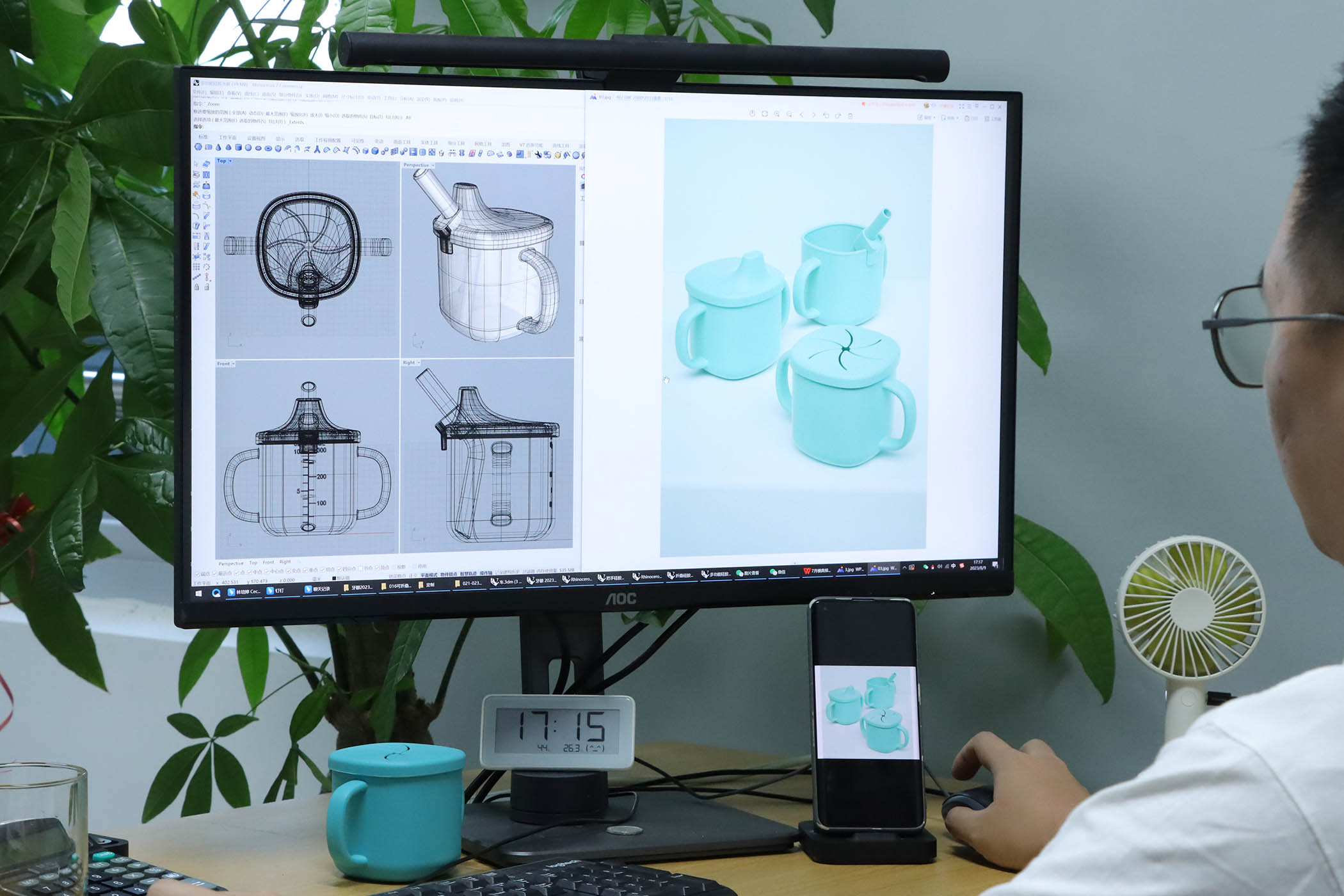

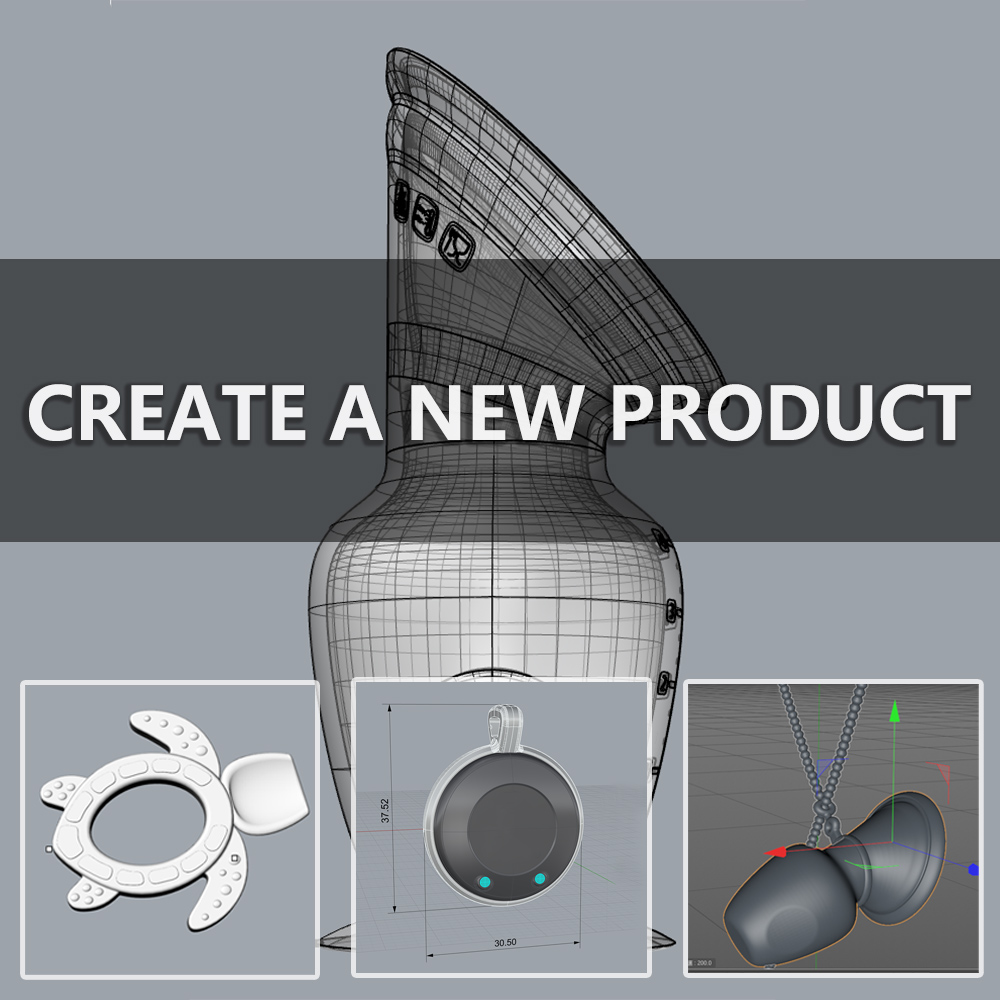

Expert Design Team

NEWTOP Rubber has a team of experienced silicone product designers. We are good at the design of various complex products. We will discuss with customers about the concept and function of silicone products. After that, we will build a digital model to make the project clearer and more evaluable. These works are done to ensure that your products are manufacturable and cost-effective. All you have to do is tell us the requirements, and then let us realize them.

Our design services include:

Concept design drafting

CAD modeling

DFM review & adjustments

Cost review

Product Label Customization Solution

Labels can convey a brand's message and values to customers. Printing a Logo on a product is the best choice to enhance brand recognition. NEWTOP Rubber can print any pattern for you in need.

Our printing methods include:

Texture printing

Screen printing

Pad printing

Debossed/embossed LOGO

Laser engraving

Epoxy printing

Flexible Choice of Silicone Materials

NEWTOP Rubber factory helps to select the silicone material with the best performance through the internal material laboratory. At the same time, we provide you with a variety of high-quality silicone materials with different characteristics. You can freely customize the performance and appearance properties of the material.

Customizable sections include:

Hardness

Elasticity

Color

Translucency

Tightness

High-temperature resistance

Corrosion resistance, etc.

In-house Precision Tooling

Thanks to our in-house mold-making workshop, we are able to flexibly respond to customers' modification needs. NEWTOP Rubber manufactures molds by CNC & EDM, which can effectively help reduce mold production time and cost. For smooth or textured parts, we also have the corresponding mold surface treatment capabilities.

Our tooling capabilities include:

mold design

Various mold materials

Mold surface treatment

Mold testing and debugging

Extensive Manufacturing Capabilities

NEWTOP Rubber masters various modern silicone molding techniques. Our factory is equipped with several automatic or semi-automatic silicone molding production lines with different efficiencies. According to your project characteristics and specific needs, we will provide you with targeted molding solutions.

Our molding methods include:

Injection molding

Compression molding

Extrusion

Multiple Shot Injection Molding

Customized Product Quality Assurance

NEWTOP Rubber is an ISO certified factory, our products have passed FDA, CE, CPC, and other certifications.

In addition, we have adopted a strict internal quality supervision system, and each product will undergo meticulous quality inspection, which can effectively ensure that the quality of the product meets expectations.

We provide high-level clean rooms for optional use.

Email: [email protected]

Phone number: +8618106969228

Address: No. 89 Tianan Road, Jimei District, Xiamen, China